The Work of Repair: Gesture, Emotion and Sensual Knowledge

by Tim Dant

Lancaster University

Sociological Research Online, 15 (3) 7

<http://www.socresonline.org.uk/15/3/7.html>

10.5153/sro.2158

Received: 6 Jan 2010 Accepted: 5 Jul 2010 Published: 31 Aug 2010

Abstract

As the pressure on limited natural resources and energy increases so the trend of the consumer society of the twentieth century towards discarding things that stop working and replacing them will shift towards recycling and repairing things. This paper contrasts the work of production with the work of repair and argues that the later is an artisanal process in tune with the species being of humans identified by Marx. Amongst the distinctive characteristics of the work of repair are the use of a complex repertoire of gestures, a variable emotional tone and the gathering of sensual knowledge. These distinctively human characteristics are not amenable to systematisation or replication in a machine process. The argument is illustrated with reference to more than sixty years of research on mechanised production in the car industry and a recent study of the work of repairing cars in local garages. Video data – here summarised with still images – is used to show the complex process of the work of repair that is explored in the light of theoretical perspectives from Leroi-Gourhan, Hendrick, and Merleau-Ponty.

Keywords: Work, Repair, Cars, Phenomenology, Material Interaction

Introduction

1.1 During much of the twentieth century, as industrial production progressively reduced the skilled work of making things, there was a continuing demand for repair work to fix things that went wrong. The work of repair takes ingenuity in identifying the problem and then a wide range of skills and tools to make the object useable again; it involves a mixture of perceptual, cognitive and manual skills that are normally associated with handcraft. But the techniques of mass production have not only reduced the number of goods that are made with craft skills, they have also led to goods that are less amenable to repair (Graham and Thrift 2007). There are good reasons why a capitalist economy not only strives to reduce dependence on skilled work in manufacture but also in post-manufacture. Skilled labour is expensive in manufacture but also in after-sales work so that returns to the manufacturer under warranty or for normal repair are very costly. If objects are disposed of rather than repaired, then the demand for new goods is sustained. The corporations that produce the material culture of modern societies have responded by making goods that are designed not to be repaired but thrown away when they cease to work. The capacity of goods to last – especially those that are mechanical, electric or electronic – has been improved with ever better engineering. And to discourage repair, goods are 'black boxed' or sealed so that it is difficult to open them and tinkering will void any manufacturer's product guarantee. By using smaller, more compact and simpler connections (rivets instead of screws, heat sealed joints instead of pushfit clips) manufacture by machine is made easier but repair by human more difficult. The progression of functionality makes older items out-dated, shifts in compatibility networks produce obsolescence (vinyl to audio tape to CD, video to DVD etc.) and planned obsolescence combine well with a fashion system that celebrates and encourages the 'new' (Campbell 1992). During the second half of the twentieth century industrialised societies became, by these various socio-technical systems, progressively more 'throw-away' (Toffler 1973).1.2 In the twenty-first century attention has begun to turn towards the environmental need to conserve resources and energy, which has led to increased interest in the recycling of goods and materials. But the work of repair has a similar role to play in shifting the material culture of postindustrial societies towards a more sustainable mode that has not yet been realised. Repairing goods can extend their useful life, postponing the need to break-up and recycle the materials as well as reducing the energy demand of manufacture. Domestic electrical and electronic equipment from toasters to portable radios, from video recorders to washing machines are the sorts of items where repair is in principle possible, but often it has become cheaper and more convenient to replace the item. Furniture, furnishings, clothes and shoes used to be routinely repaired and refurbished but it has become culturally less acceptable and so finding someone to do the work of repair has become more difficult. There are environmental gains to be made from promoting repair but there are also significant economic gains from stimulating and encouraging the work of repair in terms of creating skilled, rewarding work within those postindustrial societies that have lost skilled work to machines and through the export of manufacture in search of cheap labour. In this paper I will argue, using the example of work on cars, that the work of repair needs to be re-valued by recognising that it involves complex human qualities, which maximise the skills and autonomy of the worker.

1.3 Within the material culture of the western industrialised societies a number of strands of repair work have been sustained such as the repair of buildings and their equipment, machines in work settings (Orr 1996) and singular aesthetic objects. However, amongst the mundane objects within contemporary material culture, used by all, owned and possessed by most, the motorcar is one that continues to be regularly repaired (Borg 2007). Cars, lorries, buses and motorcycles are routinely checked and serviced which leads to the work of maintaining and repairing them. This work of repair goes on in any country where there are people and cars; in rural villages and suburbs, as well as the centres of cities and industrial areas (Harper 1987; Verrips and Meyer 2001: 165-173; Young 2001: 49; Mellström 2002; Edgerton 2006: 83; Borg 2007). Cars are repaired in a variety of different sites: in corner workshops, behind petrol stations, in large retail units, on industrial estates and on the site of car dealerships on the ring roads of cities (Edgerton 2006: 80).

1.4 In this paper I want to contrast the human, artisanal character of repair work on ordinary cars with the more alienating work of machine-based manufacture.[1] After discussing machines in the making of cars I will point to three particular humanising aspects of the work of repair –gesture, emotion and sensual knowledge – from a study of service and repair work on cars. These are all embodied capacities of human phenomenology that are so fundamental to our being that we take them for granted. Many other animals clearly have gestures, emotions and acquire sensual knowledge, but what is distinctive about the importance of these for human beings is that they are an integral part of the creative process of making that, with Marx, I take to be fundamental to human 'species being' (Marx 1975). Here I want to argue that they are also integral to the work of repair that has much in common with craft or artisanal work except that it lacks a new, finished product to show for it. I am using the word 'gesture' in a way that is a departure from its normal use in English to refer to the movements of the body and the hands for expressing thoughts or feelings to other people (Kendon 1986: 24). I am following André Leroi-Gourhan's (1993) use of 'gesture' to refer to movements of the hand and body that have a cultural meaning because of what they do; there does not need to be a symbolic code or a recipient for the action to count as a gesture. My use of emotion too is a departure from the way that it has been used by many social scientists responding to the 'affective turn' (Greco and Stenner 2008). Here emotion is a feature of the unfolding work that involves interaction between people and objects. The shape of the interaction is literally affected by the emotional orientation of the humans involved. Sensual knowledge too is an underemployed concept in sociology but has a solid foundation in phenomenology that I want to draw attention to – human knowledge cannot be reduced to its abstract, discursive or disembodied forms.

The work of manufacture

2.1 The species being of humans lies in their capacity for creativity beyond immediate need and Marx went on to describe the mode of production that exploited this excess of creative impulse through a progressively mechanised division of labour that reproduced, exactly and virtually endlessly, the gestures by which artisan workers had previously made things. Industrialised production changed not only the mode of production but also the mode of interaction between the subject of the worker and the tools and products that are the objects of their creativity (Marx 1976 – see Dant 2005: 14-18). The work of producing things that people need for living – domestic equipment, clothes, furniture, furnishings, tools, communication devices, cars and so on – has progressively been industrialised over the course of the twentieth century. But it was the mass production of cars that led the way and the Ford factory provided an exemplar of this emergent system of manufacture giving us the label 'fordism' to describe centralised industrial production dependent on capital accumulation, sophisticated machine tools, a de-skilled but high-waged labour force and a high demand for the finished product. Fordism produces standardised goods at dramatically lower prices than similar goods produced by an artisanal production system – but at a cost.2.2 As early as the 1950s Georges Freidmann was analysing the dehumanising consequences of divided, automated work. In 1948 he was told by a manager of a motorcar factory 'We try to reduce skill to a minimum' (Friedmann 1956: 2) and his subsequent investigation explored the harmful effects of replacing manual work to leave only the serving of machines with blank parts that drilled, pressed or moulded them quickly and exactly, tasks that lacked the 'balancing virtues of real work' (Friedmann 1956: 155). The problems of monotony and boredom with a mechanically controlled work pace, the minimal skill required, the predetermination of tools and techniques and the superficial mental attention needed by the auto-assembly line worker were identified early on (Walker and Guest 1952). In the late 1960s Huw Beynon studied the tedium, monotony and dullness of work on the line in UK Ford plants that meant the workers 'blanked out their minds' to get by (1973: 127). The 'degradation of work' (Braverman 1974) was associated with the way that the car industry developed machine tools and the moving assembly line to maximise the division of labour to dehumanising effect (Linhart 1981). Of course the alienation of workers had consequences in terms of industrial disputes (Beynon 1973) and falling productivity so that later in the twentieth century there were changes, most notably the introduction of 'lean production' (Womack et al. 1990). There is skilled work in mass auto manufacture (Beynon reckoned that no more than one in a hundred jobs were skilled - 1973: 126) but it is often to do with repair of the line and cars that have been improperly made. One of the things that Toyota's lean production system led to was team working and less division of labour so that the workers would be able to stop the line and fix things that had gone wrong themselves. 'Reworking' of poorly made vehicles was reduced by the 'relentless attention to preventing defects' by a workforce that was highly motivated by their job for life and involvement in managing the line (Womack et al. 1990: 78-80). A different version of team working was the 'parallelised' long cycle, whole car, 'tilted assembly' system at Volvo's Uddevalla plant in the late 1980s that closed in 1993 (Sandberg 1995). A further variant was the 'short flow' or assembly cell that fitted truck cabs in-situ introduced at Volvo during the 1990s that again, for managerial and organisational reasons, did not continue beyond 2002 (Wallace 2008).

2.3 The stress of just-in-time production, that gives the worker responsibility for managing the stock of parts on the line but no control over their delivery, is described by Laurie Graham's (1995) first hand account of work 'on the line'. Although in principle any worker can stop the line, in practice the team leader does this only when there is no alternative. Unusually in the literature, Graham does not extol the benefits of lean production but actually describes the work, including the sequence of 23 tasks she completed in a five-minute cycle of work at station 'one left', that, once completed, began again and was repeated throughout the eight-hour day. For each station the sequence of tasks is different as different components are added to the 'body' of the vehicle on the line. Some are trickier to complete in the time, others involve physically demanding tasks such as pushing grommets and clips into tight holes that, through repetition, lead to injury (Graham 1995: 84-93). Rotation of jobs – something identified back in the 1950s as a managerial response to boredom and monotony (Walker and Guest 1952) – depended on agreement from the team leader and was not routine (Graham 1952: 66-69). The Japanese system of lean production gives workers responsibility for improving work tasks through 'kaizening' their own tools, racks or sequences of action to increase the efficiency and safety of the work (Graham 1995: 105-106). However, the overall account of the work Graham gives is of dull, physically hard, intellectually undemanding, repetitive, fast-paced and pressured work with no time for thought, reflection or social interaction while the line is running. What Graham calls 'Japanese production' achieves compliance with the company's requirements hegemonically through behaviour training and a team structure that gives employees responsibility but virtually no control over their work.

2.4 In the 1950s Friedmann (1952: xvi) was anticipating the impact of computerised technology that has since extended the domination of production by automated machines. Machine tools and the moving assembly line shaped the work of car manufacture during the twentieth century and although we now think of this type of work as undertaken by computer controlled robots mimicking the gestures of human bodies, much of the 'fitting' of parts continues to be done by human workers. There are work tasks in mass car manufacture that require creativity and imagination but these are mostly in designing, selling and organisation. Those workers employed on the production line continue to have jobs that require them to repeat the same task of fitting a set of components or a part to each vehicle in exactly the same way within a strict time cycle.

2.5 Car production has provided the exemplar of mechanised industrialisation during the twentieth century but the same cannot be said of the car repair industry. It continues to be an artisanal, semi-skilled type of work that routinely confronts workers with many quite different tasks. As Kevin Borg's history of automechanics in 20th century America shows, the work processes 'resist the predicatability, regularity, rationalization, and regimentation so often associated with industrial production and the assembly line' (2007: 4). The worker in a car repair garage is daily presented with different tasks. Even when the tasks are the same (e.g. changing brake pads), each new vehicle is different – different makes, models, ages and conditions. Often the nature of the task is only imprecisely specified in advance and its actual demands only emerge as the work progresses. The repair worker's task has developed over the twentieth century from making, modifying and repairing damaged parts to almost exclusively fitting and adjusting pre-formed new parts. Nonetheless, there is an artisanal skill in identifying the source of a problem and then rectifying it by fitting appropriate spare parts. Removal of old parts can be very difficult and fitting, even of the original manufacturer's specially prepared spare parts, usually requires a range of embodied skills including imagination, dexterity, strength and finely tuned perception. The gestures required for each task can be very different and demand a varying emotional tone that affects how the work proceeds. Car repair technicians need an abstract knowledge base about how cars fit together, how their parts operate and how to use different tools but their knowledge of what to do next often depends on a sensual, embodied knowledge that is gathered in situ through interaction with the array of objects.

2.6 Unlike production line work, repair – such as that on cars – is a mode of work that continues in the twenty-first century to call on the imaginative creativity that is entailed in species being. Early in the twentieth century Thorstein Veblen described this human quality as the 'instinct for workmanship' and early in the twenty-first century Richard Sennett (2008) has celebrated once more the role of the 'craftsman'. Repair work (Harper 1987; Orr 1996; Borg 2007; Graham and Thrift 2007) is not highly skilled craftsmanship like the making of individual pieces of furniture or even contributing to the hand building of a car. But it is work that employs many of the embodied skills that are characteristic of creative human material interaction. Unlike the industrialised production of commodities, the work of repair does require a complex repertoire of gestures, a variable and responsive emotional tone, and a developed capacity for gathering knowledge of particular objects through all the senses.

Gesture

3.1 All humans in western industrialised cultures learn common gestures in relation to technical objects that are encountered in everyday life such as twisting knobs, pushing down on levers, pressing buttons. A fundamental device in industrialised society is the screw thread used to firmly join two rigid pieces – a bottle and cap, jar and lid, a screw, nut or bolt – that everyone learns to cope with. But many different types of specialised repair work involve a range of particular gestures and particular tools. The gestures needed to 'screw things together' are familiar, especially for the do-it-yourself engineer and the hobby mechanic, but skilled technicians, such as those who work on cars, learn to handle different types of screw thread (which are usually right handed, but occasionally left handed), different degrees of tightness and a range of tools, each requiring their own distinct set of gestures. The screwdriver and the spanner provide the basic forms for tools to work on objects with threads but car technicians develop skills for using ratcheted, extended and powered versions of both devices with a variety of 'bits' for engaging with screws, nuts and bolts that have different 'heads' and threads. They also adapt tools and incorporate them into gestures that are not those for which they were originally designed.3.2 Leroi-Gourhan recognises that human actions with things are also gestures in the sense that they are learnt from within the culture and have meaning in the way that they transform objects. In a series of works from the 1940s, he explored the evolutionary relationship between human beings and technology from an archeo-anthropological perspective. He distinguishes the evolution of the human form from that of apes by the ability to use both hands simultaneously while controlling the position and mobility of the body using the legs and lower torso. This produces the animal form that he calls the 'anthropomorph' – hands completely free, erect posture, with brain freed from the vertebral column and able to develop in size and so skill (Leroi-Gourhan 1993).[2] He argues that the anthropomorph is a distinct evolutionary line from the pitheomorphs – the apes – who do not share the same erect posture. This is important because the physical equipment for gesture – the muscles, bones, flexibility and so on – are present in the apes but they have not been developed to anything like the same extent as in humans. The gestures that are mechanically available to primates are much the same as those available to anthropomorphs; grasping, touching, picking, kneading, peeling, handling. Both apes and anthropomorphs can hold food while tearing it with teeth, crushing it with molars, cutting it with incisors. Both evolutionary lines can hammer with fists, scratch and dig with nails. But gesture in the anthropomorph extends beyond the mechanical capacity of the body: 'From primate to human being, grasping operations do not change in nature but develop in terms of the variety of ends pursued and the delicacy of execution… the result of a technical gesture does not require any part of osteomuscular apparatus that is not already present in the higher monkey: The difference is one of nervous apparatus alone.' (Leroi-Gourhan 1993: 239) It is the relationship between gestural capacity and brain capacity that has enabled human evolution to continue outside the body in a way largely unavailable to other species. This evolution has continued through the development of objects, gestures and practices created to meet human needs and desires. Gestures are extended in range and effect by tools that enhance the body in complex and variable ways not nearly matched by any other species. So, it is not the possession of a hand, or the mechanics that surround it, but the hand in relation to posture and brain capacity that enables the gestural complexity of humans in the realisation of species being. Of course working on a production line precisely reduces the range of gesture and the relationship between 'delicacy of execution' guided by the 'nervous apparatus'. Working on a production line requires the exact same gestures to be repeated and the only brainpower required is to coordinate bodily actions to coincide with those of a machine. The division of labour derives efficiency through the worker repeating the same sequence of actions many times over, thereby becoming fast, precise and efficient at a single work task.

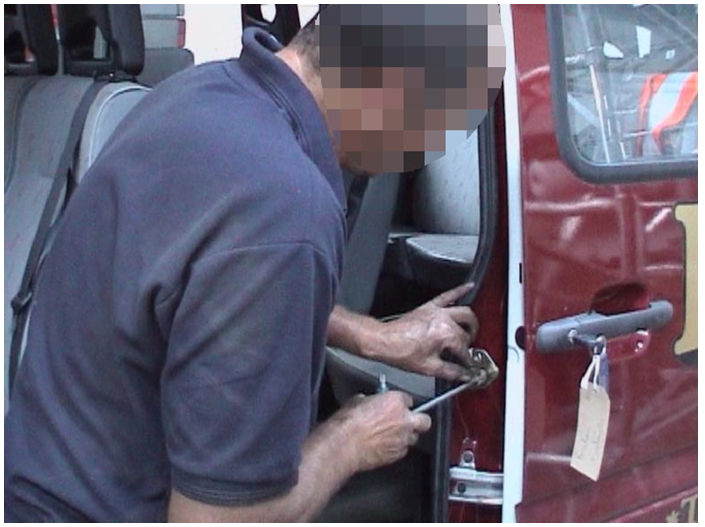

3.3 Working in the repair garage, the technician often repeats the same basic gesture many times, but usually with slight variations to make fine alterations and adjustments in the array of objects. A basic gesture that has been learnt – such as how to hold and turn a screwdriver – is shaped to fit the particular situation and then the gesture and the tool may be combined in a number of different variants on basic gestures. For example, a technician (I'll call him Reg), was observed during a field study of car repair work using a range of different gestures with a series of screwdrivers in his attempt to re-align a sliding van door to make it close smoothly.[3] The images are a sequence taken from twenty minutes of video of this job – they occur minutes apart. In Figure 1 Reg uses his hands, together as a soft hammer and in Figure 2 he is using a sort of screwdriver, one with a star head and a lever style handle, (notice the way his left-hand takes a precision grip on the fitting behind the screw head). In Figure 3 he is using the same screwdriver on a different screw with quite a different grip, the left hand now taking a precision grip to direct the head of the tool. In Figure 4 Reg is using a traditional slot-head screwdriver but this time as a lever on the middle of the door. A similar levering gesture is used in Figure 5 but here with an old-fashioned tyre lever. In Figure 6 the handle of the screwdriver is used as a wedge while his hands are used again as a soft hammer. And then in Figure 7 Reg uses a screwdriver in his right hand and the tyre lever in his left, but both for levering the door; the top one is levering the door outwards towards him, the bottom simultaneously levering it to his left. In Figure 8 he uses the tyre lever not as a lever but as a 'drift' with a ball-peen hammer to drive it.

3.4 What the sequence shows is that Reg is able to draw on a wide repertoire of gestures that incorporate a series of tools used in a series of different ways. The nature of the task develops over time so the lack of success in realigning the door early on leads to the introduction of more tools and different gestures later in the job. The tools chosen are somewhat constrained by the task so the star driver must fit the screw head and the levers must fit the slots. But neither tools nor gestures are specified by the job; they are introduced as and when Reg thinks they are appropriate. The sequence interestingly demonstrates a progression from smaller to larger tools, from finer to larger – and more forceful – gestures as the door appears to resist being realigned. Leroi-Gourhan sees this distinctly human capacity to develop gestures with the hand as linked to the capacity of the mind to develop variations and sequences of gestures that can be drawn on as situations unfold. As he puts it: 'The operational synergy of tool and gesture presupposes the existence of a memory in which the behaviour program is stored' (Leroi-Gourhan 1993: 237). Tool use requires technique which must be remembered and brought into play in a flexible and adaptable way in this type of work. Raymond Tallis takes even further the significance of the hand in making humans the particular animal they are:

3.5 The grip, unlike other motor activity, is always customised to a unique occasion; so variation is both necessary and at the same time, limited in its range…. This constrained arbitrariness is a supreme awakener, awakening the sense of the body as a tool and hence of agency. Of all bodily doings prior to the emergence of speech, those involving the hand are most developed as voluntary actions and the key to the ultimate development of the sense – that we enjoy, uniquely among the animal kingdom – of our bodies as instruments. (Tallis 2003: 204).

3.6 Reg is not creating or making an original object as we would expect from the artist or the craftsman. But characteristically of repair work he is exercising the same sorts of artisanal skills in using tools and gestures with which to transform the material world; he is using his body as an 'instrument'. This complex range of gestures (many of which are ineffective) are employed in the particular task of repair, of trying to put the material world back to how it was before damage or deterioration. If the repair is successful, then there is no trace of the complexity of the work that has achieved the transformation – the object appears simply as it should.

Emotion

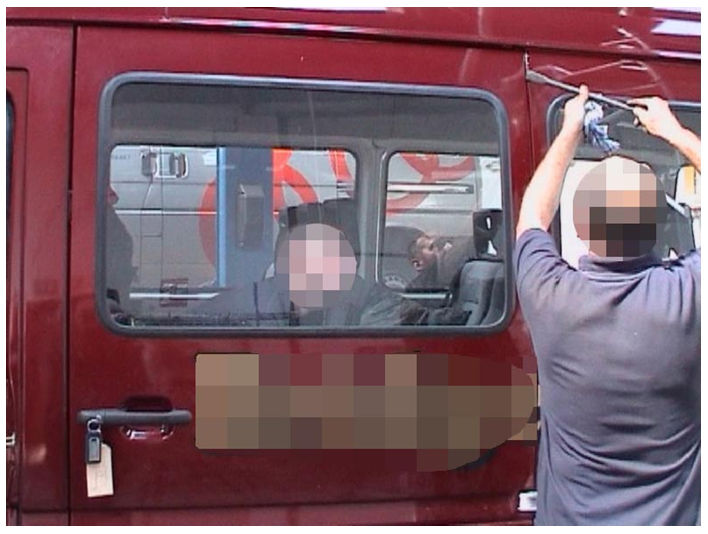

4.1 Much of the explosion of writing on emotion and affect in the social sciences over the last forty years has been concerned with the social construction of emotional states (Greco and Stenner 2008). Emotions have, for example, been studied in terms of their cultivation and projection (e.g. Hochschild 1983) their impact on society through professions (Rose 1990) and the media (Tyler 2008) but here I want to show that emotion is an aspect of the unfolding material interaction between a person and the array of things in the work of repair. Emotions work (Katz 1999) not only to shape interactions between people but also to motivate actions (Frijda 2004) and the work of repair is an opportunity for realising the variability of human feelings and expression of emotion through gestures. How the worker feels is affected by her or his sensual knowledge and will in turn affect how gestures and tools are employed as the work proceeds ( Deleuze and Guattari 1988 write of the 'passional regime of feeling' in the assemblage of the work machine – 1988: 400). Normally this is very difficult to see but in the example I want to explore from fieldwork in a different garage, the talk and demeanour of two men working together expresses the emotional tone of their material interaction with the things they are working on. One is slightly fearful and cautious, the other recognises the basis for fear but his emotional tone is more confident. For both men, the successful completion of the task leads to a release of emotional tension and a reflective sense of pride and achievement in their mastery over the tools and objects.4.2 The system of 'Japanese production' includes collective warm up exercises, team slogans, targets and 'kaizening' all of which cultivate emotional commitment to the company, the finished product and sustaining output (Graham 1995: 68-69). But the actual work on a production line requires only just enough emotional engagement to sustain the series of repeated gestures and spot things going wrong. In contrast, the work of repair depends on an emotional attention not only to the final goal but also to the unfolding task with its continually changing array of material objects, in which feelings must attune gestural response to the evolving situation. For example, in an unusual disassembly task observed at a different garage in the same study of repair work in garages, two technicians were working together to remove the subframe from underneath the front of an old Jaguar, originally built in the 1990s. At a particular phase of the job that lasts just over two minutes, the emotional tone, which had built up steadily over days, was at a much higher pitch than usual.

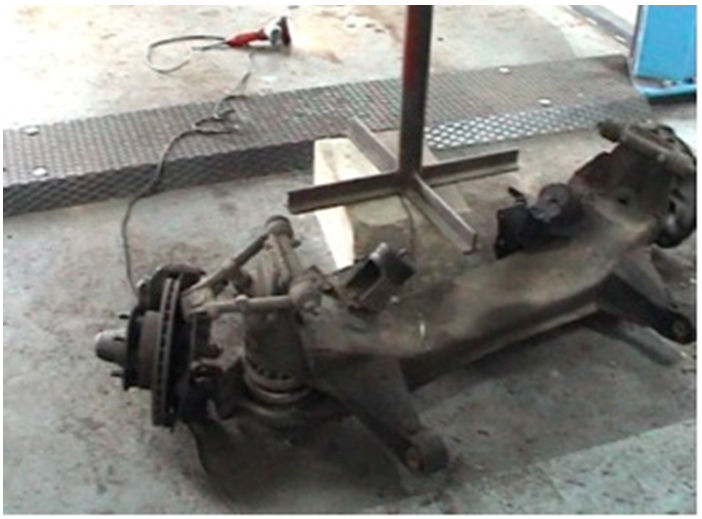

4.3 One of the mechanics, who I'll call Rick (on the left, Figures. 9-16), is doing the job of renovating the Jaguar, and the other, I'll call him Oliver (on the right) came in to help out. Rick and Oliver don't know each other well but what is clear is that Rick is very unconfident about what they are about to do. He has spent the best part of two days in the mundane work of detaching all the bits of the car such as the steering rack and controls from the subframe. But now he is nervous about whether he has understood the array of objects completely and accurately: Has he perhaps missed a bolt? Is there a connection of another sort that he didn't spot? Oliver's job is ostensibly as another pair of hands but he has also been welcomed as someone with the experience to help with a tricky task. This is a potentially dangerous job because if the subframe fell it is heavy enough to do serious injury to anyone in its path (see Figure 16). The car is up on a lift with the wheels at about head height and ropes supporting the engine from a bar across the engine compartment. Another of their fears is that as the subframe is removed, these supports fail and the engine simply drops out. The sequence of still images is taken from the tense two minutes that it takes to lower the subframe out of the car and get it onto the floor – the culmination of about eight hours preparatory work. The still images with their pixelated faces cannot communicate much of the emotional tension in the voices and the demeanour of Rick and Oliver during the short travel of the subframe as it is lowered.

4.4 They remove the last two bolts holding the subframe and then lower it slowly on a hydraulic jack with a cradle that is designed to lower gearboxes – Rick turns to the researcher and says 'I don't like this… at all!' and as it starts to move says 'Whoa… She's coming'.[4] Oliver stretches underneath the car to open and close the valve on the jack to control the rate of descent (Figure 9). At one point they are concerned that it is snagged – Rick says 'what's that tight on?' They cannot see, but they can feel through the subframe that it is not descending smoothly on the jack. Rick has to move the subframe on its axis to get it to slide around the roll bar and the steering rack. They are interpreting the changing array of objects as they move in relation to each other, through their hands and through the subframe and through their whole bodies. When Oliver stops the cradle (Figure 10), he also looks around underneath to see what might be snagging it. Things seem clear but once he opens the valve and the subframe starts to descend again they hear bits falling onto the floor and Rick remarks in a shaky voice, 'washers fallin' off everywhere' (Figure 11). Their 'visual' and 'haptic' embodied knowledge depends on having experienced similar things before. Neither of them have ever done this job before but they can feel when it is snagged or has to be manoeuvred round things, the falling washers were not expected and could indicate something in place that should have been removed.

4.5 Rick especially has face to lose as a professional mechanic – he hasn't long been in the job and doesn't want to mess this up. His is not a rational weighing up of risk, it is precisely not calculative, but is a fluid judgement that situates the person in relation to the unfolding situation. He looks nervous from the off – his voice is more hesitant and inclined to drop away, as if he is half talking to himself. Oliver takes a much cooler emotional line and much of what he says are things like 'mine is out', 'I think we're clear', 'that's clear on mine' and the reassuring 'Awright mate?' followed by the warning that the subframe 'might roll to the front slightly' as it eases past the anti-roll bars (Figure 12). Oliver's spread leg stance is firmly confident and his face looks impassive – the tone of his voice with its rich East Anglian vowels is clear and definite. The emotional tone affects how the two men interact – Oliver may be more confident but he respects Rick's nervousness. There was no 'by-the-book' way of removing the subframe; they had to work out how to do it and then have a go. They take things slowly, stopping and checking a couple of times; this is not a slapdash process, nor is it mere routine.

4.6 In the corpus of data from which this incident comes, there are other occasions when there are clues to lack of confidence although none shows quite this level of apparent emotion. What is common to this and many other examples, however, is the pleasure in achievement and the change in emotional tone once a task has been successfully completed. Rick is relieved that it went well without damage or injury and relaxes noticeably afterwards – Oliver is more phlegmatic but is quietly pleased that his command was warranted (Figure 13). These feelings of pleasure come from the exercise of what Ives Hendrick calls the 'instinct to master' (1943a; 1943b see Tisseron 1999: 134-138). Hendrick, a psychoanalyst, saw the instinct to mastery as something fundamental to human being in a similar way to Thorstein Veblen's (1964) notion of the 'instinct of workmanship'. Neither instinct is like a lower animal's innate biological drive to act in a certain way, but is an instinctive orientation towards learning to act with skill. The instinct that Hendrick writes about has the aim of 'effective and integrated performance' that can include embodied interaction with material objects. In the work of repair, mastery is in confronting the particular task on the particular vehicle and often requires imagination and creativity in improvising a solution to what seemed at first an impossible problem involving old, damaged, obscured, dirty and sometimes rusted-in parts. Mastery involves coping with unpredictability, overcoming obstacles and bringing embodied capacities together to achieve a desired outcome in a given situation. The mastery over things – understanding, manipulating and controlling the world of material things like heavy objects and tools that may fail – leads to the emotions of pleasure and satisfaction.

Sensual knowledge

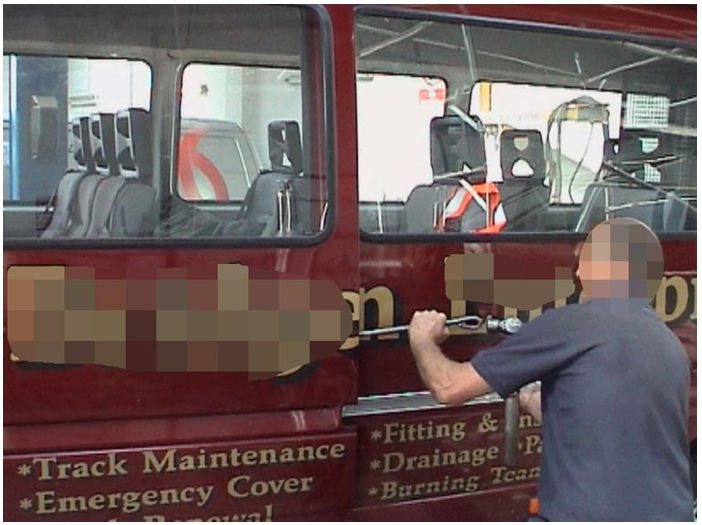

5.1 There is an argument (e.g. Borg 2007: 111) that the embodied knowledge of work with material objects should be treated as 'tacit knowledge' in Michael Polanyi's famous phrase, by which he means that 'we know more than we can tell' and that we have to 'dwell' in things to understand their meaning (Polanyi 1983: 18). This mode of non-discursive knowledge has been argued to have a place even in scientific knowledge (Collins 2001) but the concept is slippery because most of what we recognise as 'tacit' knowledge can in fact be acquired or passed on discursively. Douglas Harper nicely shows how much of the complexity of the embodied knowledge that his informant normally takes for granted without discussion can be described, especially with the prompting of photographs and an interested interrogator (1987: 118-133). But there is a mode of knowledge acquired from the material world through the senses that I will call 'sensual knowledge' that, while it can be mixed with discursive knowledge to form a diagnosis or a strategy for repair, is difficult to represent outside the body.5.2 An array of standard objects should fit together as expected if a machine tool or press has recently manufactured them (though see Graham 1995: 90). But repair work draws on subtle perceptual skills to identify how the effects of wear and damage have led components to deviate from their standard, working, form. These perceptual skills that lead to diagnosis of fault and remedy are very similar to those of a craftsman reviewing their progress in making an artefact. The cabinet-maker for example runs his hands over adjacent surfaces to learn whether they are continuous and smooth or if there are lips, grooves or steps. In working with things of all sorts, eyesight is usually paramount but, as Merleau-Ponty frequently reminds us, perception is not reducible to the workings of a single sense (e.g. 1962: 213). Perception is an embodied process in which the senses work together with the mind to learn something about the world. The eyes work with the body – as the head moves, the torso supports the head, the legs bend as necessary and the hands bring objects into viewable range. The sense of sight works in concert with the memory and imagination as well as the senses of touch and proprioception to feel surface texture, weight and density. This process of sensual knowledge is continuously monitoring the way in which limbs and tools are working. But some gestures are simply about gathering sensual knowledge to plan future actions.

5.3 Reg, whom we met using spanners and levers to realign a van door, actually spent much of his time simply trying to learn in what way the door was not working. On the video recording, many of his gestures involve eyes, hands and body but make no attempt to change any of the material objects in the array he was concerned with – he applies no force and uses no tools. Much of what he does is opening and shutting the door – from inside, from out, quickly, slowly – as testing actions during which he watches carefully what happens especially at the end of its travel. The door slides parallel to the van side along runners designed so that the final few inches guide it through an angle to fit in line with the side panel and engage with catches at front and back. During the twenty minutes of video of him working on the door he opens and shuts it 35 times – of those some are slow, just-testing-the-movement shuttings but 23 are normal full-effort shuttings to test the closing.

5.4 At the beginning of the video, Reg pushes the door gently just to – it clicks shut at the front but it doesn't close completely at the back. He is looking carefully to see how the door moves. Then he releases the door and gives it a more deliberate swing shut, the way that people who use this type of door normally shut them – with a bit of a slam. The door shuts completely this time with both catches at the front and back of the door engaging and it looks as if it works just fine. But Reg is not happy. In a section of the video recording that lasts less than a minute he begins to run his hand over the bodywork, in a thoughtful way, especially where the closed door is adjacent to body panels. Firstly he touches the middle of the door over the join, then he squats and touches lower down, looking at the bottom corner (Figure 15). As the stroking gesture of his right hand comes off the join between the surfaces of the van panels, it touches the join on his face between nose and cheek, as if emphasising his reflective engagement with the problem (Figure 16). Then he looks up, before standing up to run his hands onto the top rear corner of the door panel (Figure 17). Almost immediately his glance moves to the front of the door and his body moves, followed by his right hand, which goes to touch the top front of the door (Figure 18). From the video we can see that his glance leads where his hands follow, his body moving down, up and to the left to support his visual and haptic apparatuses. What is very difficult to see on the video is that there is a much wider gap at the front of the door than there is at the back. Early in the job he had said quietly to the researcher 'needs to go a little bit higher and in a bit more' after he had failed to get the catch at the back to shut. He solved that problem by adjusting the mountings to get it a little bit higher but still he was not satisfied. Then about five minutes later he turned to the researcher and said 'tremendous gap here isn't it?' as he was touching the gap at the front of the door. Then, a further six minutes later, the video shows him explaining the problem to a mate, George, who he wants to assist him. Reg indicates, by putting his finger into each gap in a measuring gesture, that the one at the front is still much bigger than the one at the back. He points at a nearby van with a similar door for George to compare. Reg says 'y' see the difference?' and George says 'oh yeah'.

5.5 Reg brings some important embodied knowledge to the situation; he knows how a door should shut on one of these vans and he knows that the gaps at front and back of the door should be about equal. He also knows that the door should be flush or level with the body panels adjacent to it once it is shut. As he gathers sensual knowledge about this van door he learns that the gap is bigger at the front and that the door is slightly bent at the back. His previous knowledge tells him this is not as it should be and the comparison between it and how the door is now, as it changes slightly while the work progresses, tells him how to proceed. If the van door continues in its warped, misaligned state, to require a hefty shove to get it to move quickly enough to close properly, its users will notice. But if it opens and clicks shut with a single steady push each time, then they will treat it as normal.

Conclusions

6.1 Working with things may seem at first glance to be merely mechanical (indeed those who work on cars to service and repair them used to be known as 'mechanics') and the word 'mechanical' suggests something machine-like, systematic, predictable, precise and exact. In fact the work of repair presents a wide variety of broadly similar tasks that are in detail quite different. From a corpus of data on repairing cars I have used three detailed analyses to show that repair work involves a situated and emerging process, an unfolding flow of material interaction between the worker and the array of objects. This is very different from the systematised and programmed work of modern production described by Laurie Graham (1995). Repair work has a logic that is internal and particular to the task and often develops in unpredictable ways, which is why the repairer has to be able to draw on a wide range of gestures and tools that extend the human capacity to transform material objects. Because the process of repair is not easy to plan or predict, it demands an emotional engagement that can adjust the human attention, sensitivity and effort to the objects being worked on. However, completing a repair task, especially if it has been tricky or unusual, rewards the worker with the pleasure and satisfaction of having achieved mastery over the tools and objects. Finally, repair work depends on the gathering of sensual knowledge as the work proceeds. Things that require repair first need some sort of diagnosis of the fault that needs to be rectified. But diagnosis itself is often an unfolding process that is continuous with the work of repair – that something is broken or damaged is apparent even to the user but precisely what needs to be changed for it to operate properly often only emerges as the work of repair proceeds.6.2 Douglas Harper is dismissive of the 'parts changer' and the 'rationalized repairman' (1987: 117) as he extols the embodied knowledge and 'kinesthetic correctness' in the method of Willie, his exceptional informant. Kevin Borg is impressed by the traditional skill of diagnosing and tuning an engine using information from all the senses including the sounding-rod diagnosis and contextual sounds that are part of the technique of his iconic mechanic Spencer Yunick, 'America's seat-of-the-pants mechanic' (2007: 112, 167). I have chosen examples that are part of the ordinary work of contemporary motor vehicle repair work which involves no making of parts or tuning of engines, to argue that even mundane repair through removing and replacing parts is still visceral, haptic, and sensual. Repair work is artisanal in that it draws on distinctly human capacities that are not subordinated to machines even though they are applied to machines. These skills are to do with an embodied interaction between the repairer and the object that draws on the whole body, both physical dexterity and strength and the capacities of an imaginative mind informed by previous experience.

6.3 What I have argued in this paper through the illustrative examples and comparison with manufacture is that the work of repair involves the distinctively human complexity of artisanal work. It demands gestural skill, emotional engagement and the capacity to gather sensual knowledge through embodied perception. The repair worker draws on a repertoire of gestures and tools iteratively according to imagination, experience, emotional engagement and sensual knowledge rather than by following a system or a repeated sequence. However, unlike the artisan who makes something in which her or his capacities are made material and apparent, in repair work there is no finished product to display the embodied skills employed. Getting something repaired is recognised as a 'distress purchase' that gives little satisfaction to the consumer. Despite the pleasure in mastery felt by the repairer, the invisibility of their work to the user or consumer, along with its manual and dirty character (Dant and Bowles 2003), has led to the progressive devaluing of repair work during the twentieth century. Over the same period, the increasing demands for ever more complex material goods led to the mechanisation and then computerisation of production, which dramatically reduced the cost of goods while increasing their reliability and consistency. In the twenty-first century there are two reasons why repair work must be re-valued: firstly because the limits on raw materials and energy mean that material objects need to be recycled and reused as much as is possible; and secondly because repair work allows the worker to realise their species being through the application of imagination, emotion and embodied skills. The repertoire of gestures, the variable range of emotions and the flexible gathering of sensual knowledge needed for repair work are all distinctively human capacities that are very difficult to reproduce in a machine. Designing things to be repaired and encouraging consumers to extend the useable life of their goods through repair, will not only help the environment, it will create much needed artisanal work within the industrialised societies that realises human potential and is less alienating than machine manufacture.

Figures 1-8: Gesture

|

| Figure 1. Hands as soft hammer |

|

| Figure 2. Star screwdriver (grip 1) |

|

| Figure 3. Start screwdriver (grip 2) |

|

| Figure 4. Screwdriver as lever |

|

| Figure 5. Tyre lever as lever |

|

| Figure 6. Screwdriver as wedge |

|

| Figure 7. Two levers |

|

| Figure 8. Tyre lever as drift |

Figures 9-16: Emotion

|

| Figure 9. 0:20:20 |

|

| Figure 10. 0:38:15 |

|

| Figure 11. 0:53:15 |

|

| Figure 12. 1:08:01 |

|

| Figure 13. 1:43:13 |

|

| Figure 14. The subframe removed |

Figures 15–18: Sensual knowledge

|

| Figure 15. 0:25:18 |

|

| Figure 16. 0:27:16 |

|

| Figure 17. 0:34:02 |

|

| Figure 18. 0:37:18 |

Notes

1It is men that usually do car repair work in the UK and we met no women technicians during the study that this paper draws on. While it is likely that the social circumstances of the workplace may be unattractive to many women (see Figures 9-14), we saw nothing in the material interaction of the work itself that might have disadvantaged women – the types of tools available mean that sheer strength is very seldom crucial. As Laurie Graham's account clearly documents, women do the same sorts of work alongside men in car manufacture (1995).2'Those whose body structure corresponds to the greatest freeing of the hand are also those whose skull is capable of containing the largest brain, for manual liberation and the reduction of stresses exerted upon the cranial dome are two terms of the same mechanical equation' (Leroi-Gourhan 1993: 60).

3The study (see the acknowledgements) involved fieldwork in five local garages of different sizes and organisational structure over a period of seven months in 2001/2. The principal form of data gathered was video of repair and maintenance work as it proceeded normally; the research was designed not to interfere with the flow of ordinary commercial work.

4The field researcher and camera operator was Dr David Bowles, research associate on the project. I'm grateful to David for his assistance not only in gathering the video data but also for his insights in the early stages of its analysis.

Acknowledgements

This paper draws on the project, 'Car Care: The Professional Repair and Maintenance of the Private Car', that was conducted at University of East Anglia in 2002 and was funded by ESRC Small Grant No: R 00023370. I would like to thank Dr. David Bowles who undertook the fieldwork and participated in every aspect of the project.References

BEYNON, H. (1973) Working for Ford, London: Allen Lane.BORG, K. L. (2007) Auto Mechanics, Baltimore: Johns Hopkins University Press.

BRAVERMAN, H. (1974) Labour and Manopoly Capital: The Degradation of Work in the Twentieth Century, New York: Monthly Review Press.

CAMPBELL, C. (1992) 'The desire for the new: Its nature and and social location as presented in theories of fashion and modern consumerism', in R. Silverstone & E. Hirsch (eds) Consuming Technologies: Media and Information in Domestic Spaces, London: Routledge.

COLLINS, H. M. (2001) 'What is tacit knowledge?' in T. Schatzki, K. Knorr Cetina and E. von Savigny (eds.) The Practice Turn in Contemporary Theory, London: Routledge.

DANT, T. and BOWLES, D. (2003) 'Dealing with Dirt: Servicing and Repairing Cars' Sociological Research Online, Vol. 8 (2),

DANT, T. (2005) Materiality and Society, Maidenhead: Open University Press.

DELEUZE, G. & GUATTARI, F. (1988) A Thousand Plateaus: Capitalism and Schizophrenia, London: Athlone Press.

EDGERTON, D. (2006) The Shock of the Old: Technology and global history since 1900, London: Profile Books.

FREIDMANN, G. (1956) The Anatomy of Work: The implications of specialisation, London: Heinemann.

FRIJDA, N. (2004) 'Emotions and Action' in A.S.R. Manstead, N. Fijda & A. Fischer (eds) Feelings and Emotions: The Amsterdam Symposium, Cambridge: University of Cambridge Press.

GRAHAM, L. (1995) On the Line at Subaru-Isuzu: The Japanese Model and the American Worker, Ithaca: ILR Press.

GRAHAM, S. and THRIFT, N. (2007) 'Out of order: Understanding Repair and Maintenance', Theory Culture and Society, Vol. 24 (3), pp. 1-25.

GRECO, M. & STENNER, P. (2008) Emotions: A Social Science Reader, London: Routledge.

HARPER, D. (1987) Working Knowledge: Skill and Community in a Small Shop, Berkeley: University of California Press.

HENDRICK, I. (1943a) 'Work and the Pleasure Principle' Psychoanalytical Quarterly, pp. 311-329.

HENDRICK, I. (1943b) 'Discussion of the 'Instinct to Master'' Psychoanalytical Quarterly, pp. 561-5.

HOCHSCHILD, A. (1983) The Managed Heart: Commercialization of Human Feeling, Berkeley: University of California Press.

KATZ, J. (1999) How emotions work, Chicago: University of Chicago Press.

KENDON, A. (1986) 'Current Issues in the Study of Gesture' in J-L. Nespoulous, P. Perron, A. Roch Lecours (eds) The Biological Foundation of Gestures: Motor and Semiotic Aspects, Hillsdale, New Jersey: Lawrence Erlbaum Associates.

LEROI-GOURHAN, A. (1993 [1964]) Gesture and Speech, Cambridge, Massachusetts: MIT Press.

LINHART, R. (1981) The Assembly Line, Amherst: University of Massachusetts Press.

MARX, K. (1975) "Economic and Philosophical Manuscripts", in Early writings, London: Penguin.

MARX, K. (1976) Capital: Volume One, London: Penguin Books.

MELLSTRÖM, U. (2002) 'Patriarchal Machines and Masculine Embodiment', Science, Technology and Human Values, Vol. 27 (4), pp. 460-478.

MERLEAU-PONTY, M. (1962) Phenomenology of Perception, London: Routledge.

ORR, J. E. (1996) Talking about machines: An Ethnography of a modern job, Ithaca: Cornell University Press.

POLANYI, M. (1983 [1966]) The Tacit Dimension, Peter Smith: Gloucester, Massachusetts.

ROSE, N. (1990) Governing the Soul: The shaping of the private self, London: Routledge.

SANDBERG, Å. (ed.) (1995) Enriching Production: perspectives on Volvo's Uddevalla plant as an alternative to lean production, Aldershot: Avebury

SENNETT, R. (2008) The Craftsman, London: Allen Lane.

TALLIS, R. (2003) The hand: A philosophical inquiry into human being, Edinburgh: Edinburgh University Press.

TYLER, I. (2008) 'Chav Mum, Chav Scum: Class disgust in contemporary Britain', Feminist Media Studies, Vol. 8(1): 17-34.

TOFFLER, A. (1970) Future Shock, London: Bodley Head.

TISSERON, S. (1999) Comment l'esprit vient aux objets, Paris: Aubier.

VEBLEN, T. ([1914] 1964) The Instinct of Workmanship: and the state of the industrial arts, New York: Augustus M. Kelly and the Sentry Press.

VERRIPS, J. and MEYER, B. (2001) 'Kwaku's Car: The Struggles and Stories of a Ghananian Long-Distance Taxi-Driver' in D. Miller (ed.) Car Cultures, Oxford: Berg.

WALLACE, T. (2008) 'Cycles of Production: from assembly lines to cells to assembly lines in the Volvo Cab Plant', New Technology, Work and Employment, 23 (1-2), pp 112-124.

WALKER, C. and GUEST, R.t H. (1952) The Man on the Assembly Line, Cambridge, Mass: Harvard University Press.

WOMACK, J. P.; JONES, D. T.; ROOS, D. (1990) The Machine that Changed the World, New York: Free Press.

YOUNG, D. (2001) 'The Life and Death of Cars: Private Vehicles on the Pitjanjatjara Lands, South Australia' in D. Miller (ed.) Car Cultures, Oxford: Berg.